Polycarbonate Deburring Media Use For Cryogenic Deflashing

Cryogenic deflashing media is a specialized tool used in various industries for deflashing or deburring purposes. It is widely used in the manufacturing, automotive and aerospace industries where precision deflashing and surface finishing are critical. This product is made of high-quality materials that can withstand extreme conditions for strength and durability. In summary, Cryogenic deflashing media is a must-have tool for any industry that requires precision deflashing and surface finishing. Its precise cutting capabilities, durability and versatility make it the ideal solution for those who value quality,helping many manufacturers and technicians achieve their desired results with ease, and we believe it can do the same for your business. Using the Cryogenic deflashing media and you are sure to see an increase in the quality of your work.

Parameter

| Specifications | 0.4 0.5 0.8 1.0 1.2 1.5 mm |

| Colors | white, green, pink |

| From | Japan China America Korea |

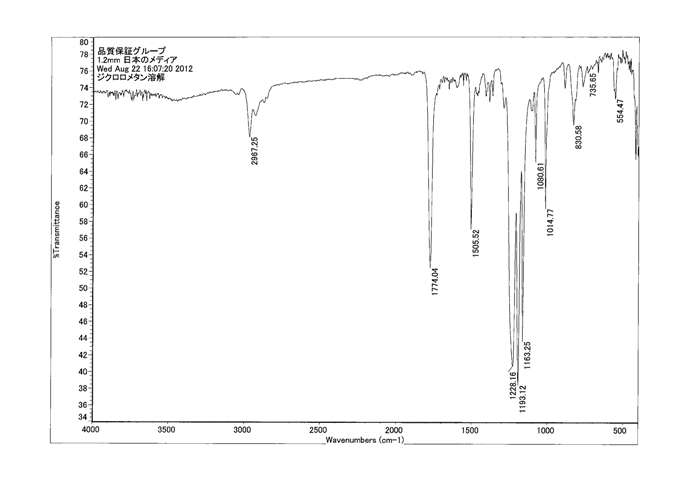

Cryogenic deflashing media composition analysis

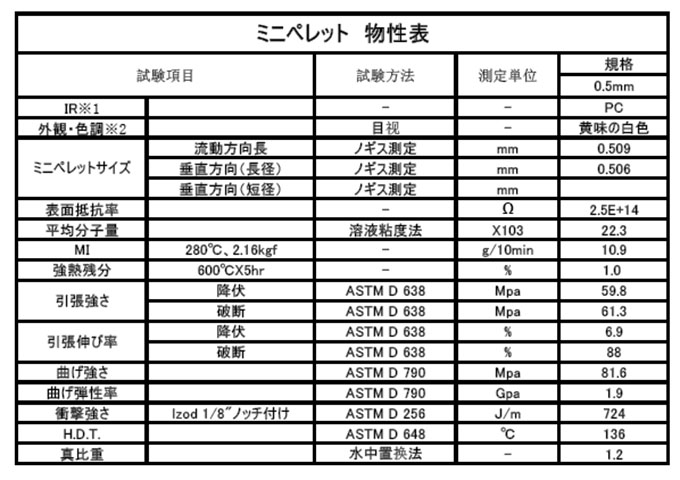

Physical property table

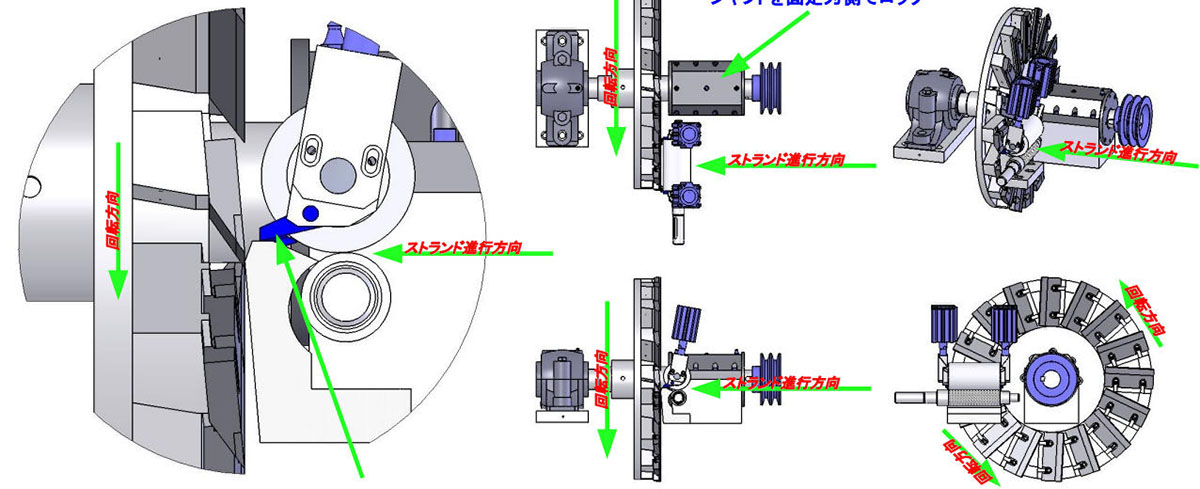

Media cutting machine

Component Analysis

Sample Name: Polycarbonate sample material.

Sample Character: Yellowish solid microspheres granular.

Detection Result

|

Number |

Component name |

Purity |

Notes |

|

1 |

Polycarbonate |

98.8% |

PC |

|

2 |

Titanium dioxide |

1% |

Ti02 |

|

3 |

silicate |

0.2% |

Sodium aluminosilicate potassium salt (similar to mineral clay) |

Excellent Performance

STMC offers a full line of cryogenic and ambient deflashing/deburring media. The media is fast and cost-efficient, quickly deflashing molded rubber and plastic parts without damaging equipment or the final product.

We company use cryogenic deflashing media every day in our own OEM Center, so we are confident in its performance. Every cryogenic deflashing media is thoroughly tested in actual field conditions to ensure product performance and reliability.

We reserve an extensive inventory of cryogenic deflashing media for excellent turnaround on most orders.

Detailed Display

Cryogenic deflashig media