When it comes to determining whether it is worth investing in a cryogenic deflashing machine in a rubber manufacturing assembly line, we cannot provide a definite answer as it depends on specific circumstances and requirements. However, through some examples, we can help you better understand the advantages and applications of a cryogenic deflashing machine. Many customers may not be familiar with the precision and efficiency of edge trimming achieved by this machine. Today, we will demonstrate its application using the processing of silicone straws as an example. (The following image is a real-time photo taken with a smartphone camera)

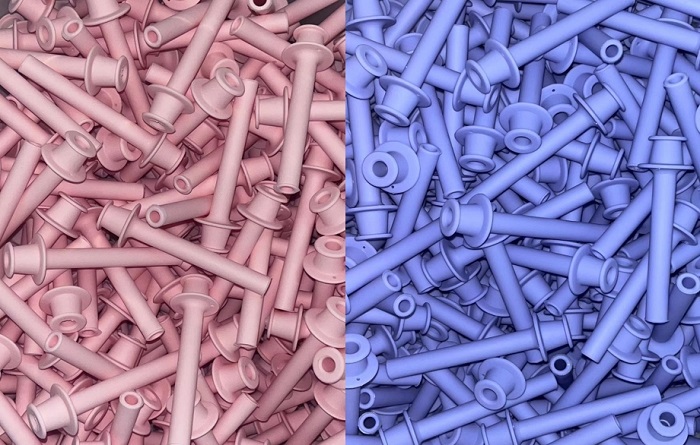

Understanding the material and shape of a product is crucial in determining whether it can be edge trimmed. When the size, thickness of the edges, and material of the product are all suitable for cryogenic deflashing, we can measure the thickness of the rough edges to be trimmed. The image above shows the state of a silicone straw under normal viewing conditions, revealing slight rough edges distributed around the mouth and casting lines. Due to the product’s usage for export, high precision and cleanliness are required. A cryogenic deflashing machine can provide a highly precise edge trimming effect, making it particularly suitable for fine edge trimming of rubber products. The cryogenic deflashing machine ensures consistency and quality in edge trimming, thereby enhancing the reliability and performance of the product. The silicone straws are processed in batches according to their colors.

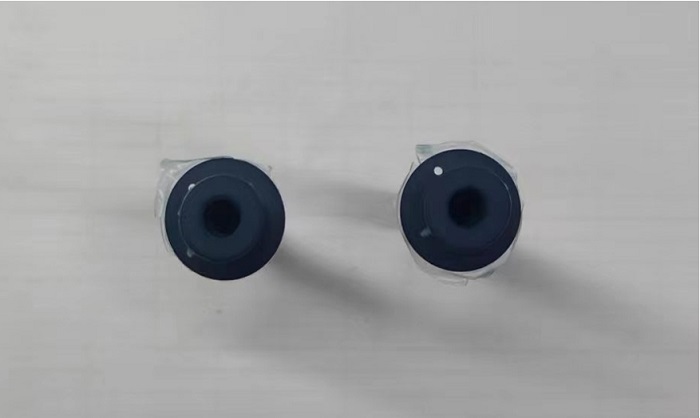

We selected straws with thicker rough edges for measurement in order to facilitate comparison in subsequent steps. Then, we placed the straws in a cryogenic deflashing machine for edge trimming. The cryogenic deflashing machine uses low-temperature cooling to make the straws harder and more stable. The brittle rough edges are then struck with projectiles to achieve precise trimming. The machine used is the NS-120C. It takes around 50 workers 2-3 days to manually trim the straws in this batch, and the cleanliness accuracy cannot be compared to that of the machine.

After the edge trimming is completed, we will measure the straws again and compare them with the dimensions before trimming. This will visually demonstrate the precision of the cryogenic deflashing machine. In addition to that, we will also showcase the edge trimming process on Zhaoling’s Tiktok, including the parameter settings for the straws and the cleaning process after trimming. This will help everyone understand the workflow and steps involved in the edge trimming process.

Post time: Sep-22-2023