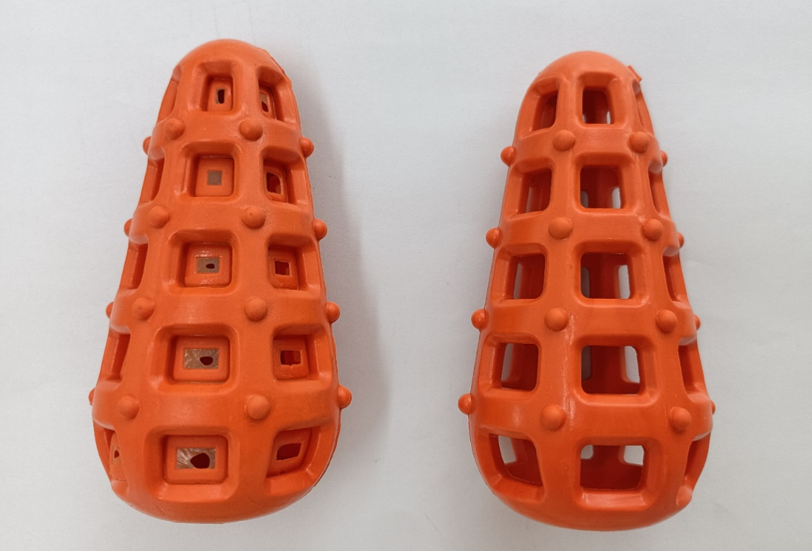

In recent years, influenced by the social environment, more and more families are keeping pets, which has led to the flourishing of the pet market and pet supplies market. The various pet toys in pet stores are dazzling, but upon closer inspection, the quality control of pet supplies in the domestic market is worrying. Many manufacturers are limited by technology in making pet toys, and their quality control is somewhat sloppy. For example, the rubber pet toy in the picture below, with its round shape and hollow design, is intended to hold snacks inside and train the pet’s biting ability through a reward system. However, many manufacturers leave a lot of burrs at the holes when casting the mold, manual burr removal is troublesome and can easily leave burrs behind. If pets accidentally ingest these burrs, it can pose a health hazard.

STMC conducted edge deflashing tests on this type of product, using the NS-180 model for mass production. The product is uniformly orange in color, resembling a carrot in shape. After demolding, there are burrs remaining at each hole, and manual burr removal requires a large amount of labor.

The NS-180 model has the following features:

- 160-180L ultra-large volume, suitable for manufacturers producing large-sized products in large quantities.

- Suitable for products with large volumes, such as rubber toys, mouse shells, insoles, etc.

Due to the lack of large-scale testing on carrots, we will take the example of a mouse shell with a similar volume. We introduced an NS-180 cryogenic deflashing machine, which processes approximately 288 pieces per hour, while manual processing handles about 45 pieces per hour. Therefore, the cryogenic deflashing machine’s hourly efficiency is five times that of manual labor.

Post time: Jun-12-2024