Cryogenic Deflashing Technology: Efficient Removal of Micro Burrs

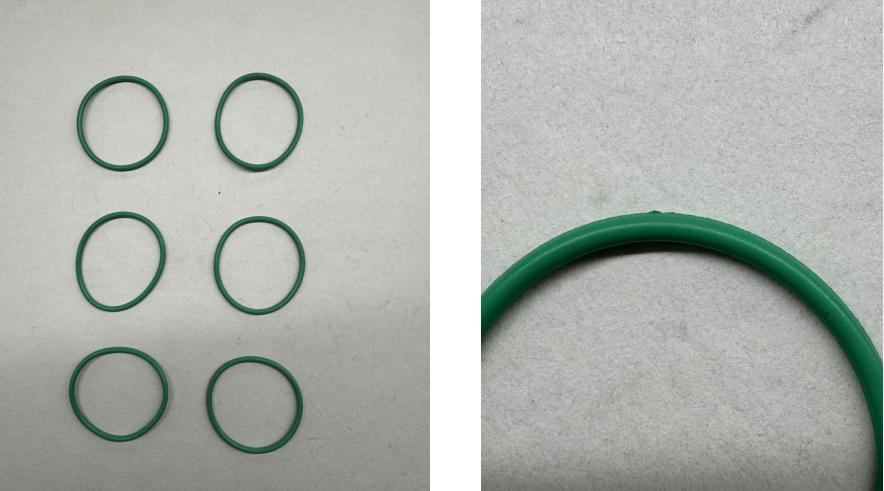

Rubber O-rings, as common sealing components, have surface quality that directly impacts their performance and lifespan. In this test, the burrs on the product surface were minimal, measuring approximately 0.4mm under high-magnification lenses. Traditional deflashing methods often struggle to completely remove such tiny burrs, while cryogenic deflashing technology successfully addressed this challenge with its unique advantages.

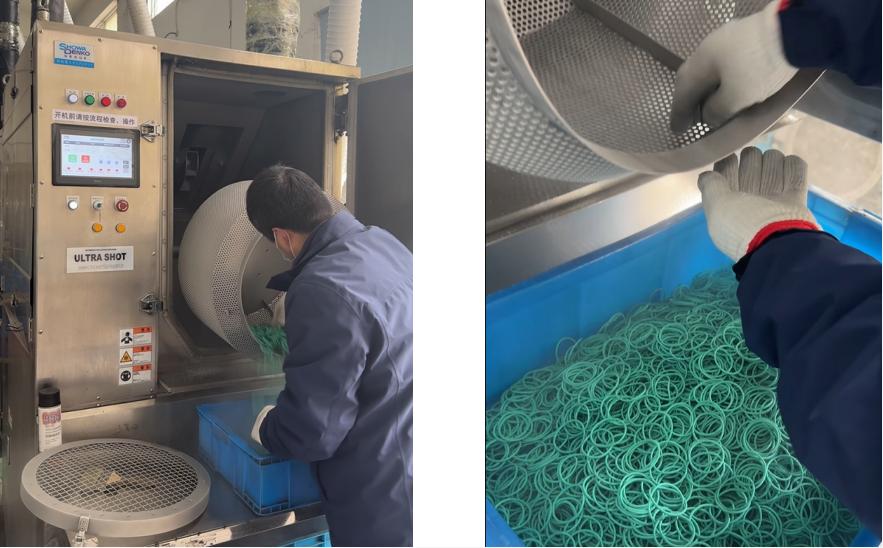

The NS-120T Cryogenic Deflashing Machine, a high-precision, large-capacity device, is equipped with a φ350 aluminum alloy impeller and can perform deflashing at extremely low temperatures (as low as -130°C). Its 10-inch touchscreen interface is user-friendly, allowing quick setup of parameters such as rotation speed, force, duration, and temperature. This makes it ideal for manufacturers with fixed product specifications and high-volume production needs.

Simple Operation, Outstanding Deflashing Results

During the test, operators first placed the rubber O-rings into the machine’s part basket, secured the basket cover, and closed the chamber door. After setting the appropriate deflashing parameters based on product characteristics, the machine was started. The entire deflashing process lasted about 10 minutes, during which the equipment operated stably with low noise and energy consumption.

Once deflashing was complete, the operators opened the chamber door and retrieved the products. Since the products were at a very low temperature immediately after removal, protective gear was worn to prevent frostbite. After the products returned to room temperature, a quality inspection was conducted. The results showed that the burrs were completely removed, and the product surfaces were undamaged, fully meeting the customer’s quality requirements.

Cleaning, Drying, and Delivery with High Customer Satisfaction

To ensure product cleanliness, the rubber O-rings were cleaned and dried after deflashing before being shipped back to the customer. The customer highly praised the deflashing results, noting that the cryogenic deflashing technology not only improved the product’s appearance but also significantly enhanced production efficiency.

Post time: Mar-04-2025