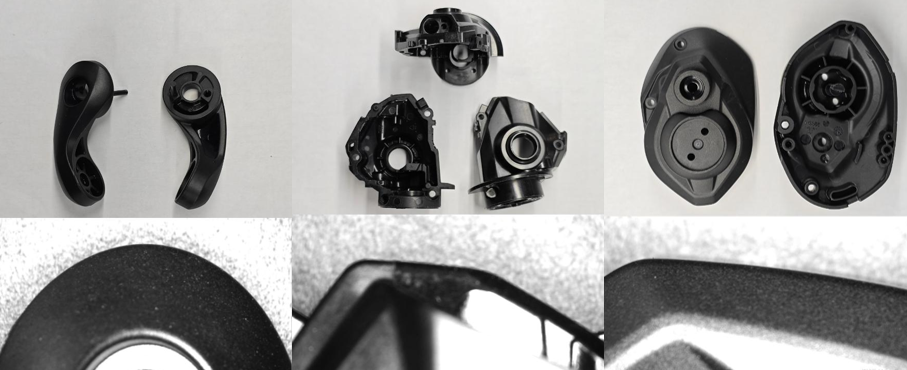

Today, the product undergoing cryogenic deflashing is a fishing tackle accessory, which is made of PA + GF material. The burr thickness observed under an electron microscope is around 0.3mm. There are a total of five models of the product, with average dimensions similar to a mouse shell. Due to the complex structure, manual edge trimming is quite cumbersome, so we are trying to use a cryogenic deflashing machine for the

The current issue is: The test machine used is the NS-60C model, and the size of the media is 0.5mm. After placing the product into the cryogenic deflashing machine’s barrel and closing the door, the parameters are set, and the machine starts running. The running time is about ten minutes.

The NS-60 series cryogenic deflashing machine has the following features:

1. Ultra-high precision, suitable for manufacturers with high precision requirements.

2. Suitable for manufacturers with multiple varieties, small batches, and variable processing parameters.

The current issue is: After the cryogenic deflashing , the product shows no burr residue under the electron microscope, indicating that products made of PA+GF material are very suitable for cryogenic deflashing machine.

Post time: Jun-19-2024