News

-

Struggling with Polyurethane Burrs?

Recently, STMC successfully tackled the batch deflashing challenge for polyurethane precision parts in the medical industry with its self-developed US-60 Cryogenic Deflashing Machine. While ensuring zero damage to product surfaces, the solution significantly improved production efficiency and pro...Read more -

UC-600 Industrial Cleaning and Drying Machine: Providing an Integrated Solution for Precision Cleaning Post-Processing

As a leading innovator in cryogenic deflashing technology, STMC introduces its latest product, the UC-600 Multi-functional Cleaning and Drying Machine. Designed to enhance precision manufacturing post-processing workflows, the UC-600 effectively removes media residues and contaminants from workpi...Read more -

How to Achieve Flawless Deflashing for 1mm Precision O-Rings?

Recently, STMC in Nanjing undertook a batch of fluorocarbon rubber (FKM) O-rings with a cross-sectional diameter of only 1mm, produced by a client, and provided cryogenic deflashing processing services. Challenges and Opportunities Coexist: The Pursuit of Precision in Delicate Parts Fluorocarbon ...Read more -

Parting line flash proving tough to remove? STMC’s cryogenic deflashing provides the “perfect solution”.

A customer manufacturing nitrile rubber rings encountered persistent, fine residual flashing along the parting lines after initial trimming with a spinning machine. This issue not only affected product appearance and dimensional accuracy but also posed potential risks to subsequent assembly and p...Read more -

How are zinc alloy die-cast parts deburred using cryogenic deflashing

Today, we conducted our standard cryogenic defalshing/deburring test on seven different types of zinc alloy die-cast parts. As a mandatory step before every batch of contract processing or equipment delivery, STMC dedicated zinc alloy cryogenic deflashing/deburring machine once again demonstrated...Read more -

Say Goodbye to Rough Edges! STMC Offers Cryogenic Deburring Services for PU Shock Absorbers

Today, parts need to be more precise. Traditional trimming methods often can’t meet the high standards for polyurethane (PU) shock absorbers. To solve this, STMC now offers cryogenic deburring services for PU shock absorbers. We use advanced technology to help improve your product quality. ...Read more -

STMC Successfully Tests Cryogenic Deflashing for NBR O-Rings, Helping Overseas Client Save Costs

STMC recently completed a cryogenic deflashing test for a variety of nitrile (NBR) O-rings sent by an overseas client. The products came in four different sizes and were originally produced using tear-trim molds. While suitable for manual trimming, these molds result in thicker flash grooves and ...Read more -

News Release: STMC Sets New Standard for PPS Injection Molded Part Finishing with Advanced Cryogenic Deflashing Technology

PPS, a high-performance engineering plastic valued for its excellent heat resistance, chemical resistance, and mechanical strength, is widely used in manufacturing precision components for automotive, electronics, aerospace, and other industries. However, its high rigidity and strength make the f...Read more -

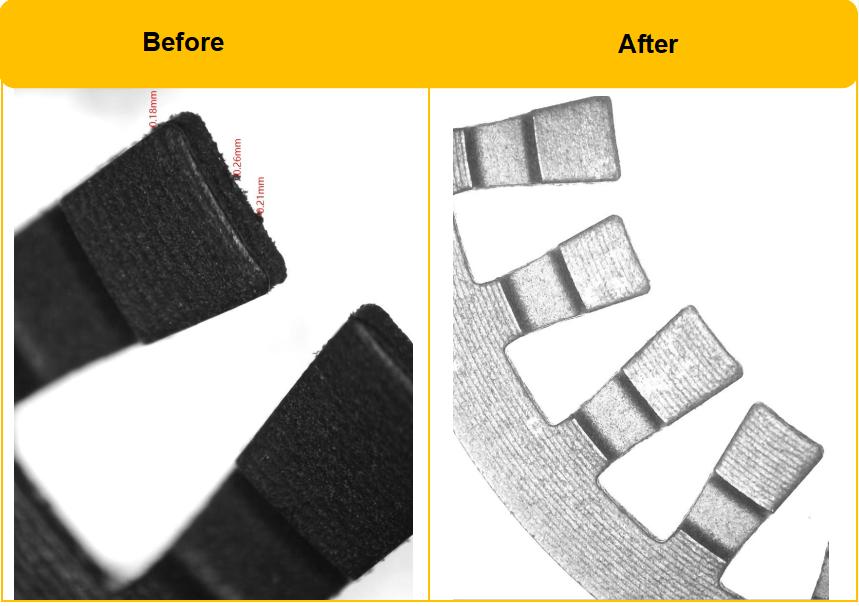

STMC: Efficient Cryogenic Deflashing for Polyurethane Gears

STMC brings two decades of dedicated expertise in cryogenic deflashing technology, integrating R&D, manufacturing, and sales to offer complete solutions, including professional deflashing services. A recent application involved deflashing a batch of polyurethane sun gears for a customer. The ...Read more -

Breakthrough in Deburring: Successful Cryogenic Deburring Test for PBT + Glass Fiber Injection Molded Parts

Recently, the technical laboratory at STMC successfully completed a cryogenic deburring test on a sample PBT (Polybutylene Terephthalate) + glass fiber reinforced injection molded component submitted by a client. The test results confirmed that the advanced Cryogenic Deflahing Machine effectively...Read more -

Got a Troublesome Zinc Alloy Toy Car with Flashes? See How STMC Delivered a Perfect Finish

Recently, STMC received a special “test case”—a sample zinc alloy toy car from an overseas client. The challenge was clear: address the problematic flashing, particularly along the parting lines and gate areas. The client’s goal was to find a high-efficiency, non-destructive fin...Read more -

How can burrs on plastic gears be removed?

In the injection molding industry, the quality of molded parts is crucial. This is especially true for precision molded gears, as their quality directly impacts the performance and stability of the entire mechanical equipment. However, removing internal burrs from these precision gears has long b...Read more