FEATURED

PRODUCTS

Ultra Shot

Cryogenic Deflashing Machine Series

Our corporate vision is to provide all customers with the best quality cryogenic deflashing machine.

You can remove burrs from your rubber parts, Polyurethane, Silicone, Plastic, Die-casting and Metal Alloy Products to ensure a safe, smooth and visually appealing surface finish with advanced deburring solutions from STMC. We offer a variety of configuration options to suit different requirements and price range.

Efficiency:

Taking the processing of regular rubber O-rings as example, One set of Ultra Shot 60 series cryogenic deflashing machine can process up to 40kg per hour, the efficiency is nearly equivalent to 40 people working manually.

Working Principle

of Cryogenic Deflashing/Deburring

Rubber, injection-molded, and zinc-magnesium-aluminum alloy products undergo hardening and embrittlement as temperatures decrease, progressively losing their elasticity. Notably, below their embrittlement temperature, even minimal force can cause these materials to shatter. At low temperatures, the flash (excess material around the product) embrittles more rapidly than the product itself. During the critical window where the flash has embrittled but the product retains its elasticity, high-speed spraying of specially designed plastic pellets is used to impact the product. This process effectively removes the flash without compromising the integrity or quality of the product.

ABOUT

STMC

Showtop Techno-machine Nanjing Co., Ltd. is a Chinese national high-tech enterprise, for over 20 years STMC has been specializing in the R&D, manufacturing, sales & lifetime post-sales service, spare parts and consumable supplies of cryogenic deflashing machine and OEM service. Do well in rubber, silicone, peek, plastic material product deflashing & deburring.

STMC has its global headquarter in Nanjing, China, south region subsidiary in Dongguan, West region subsidiary in Chongqing ,oversea branches in Japan and Thailand, committed to serving clients around the world.

Our

Customers

recent

NEWS

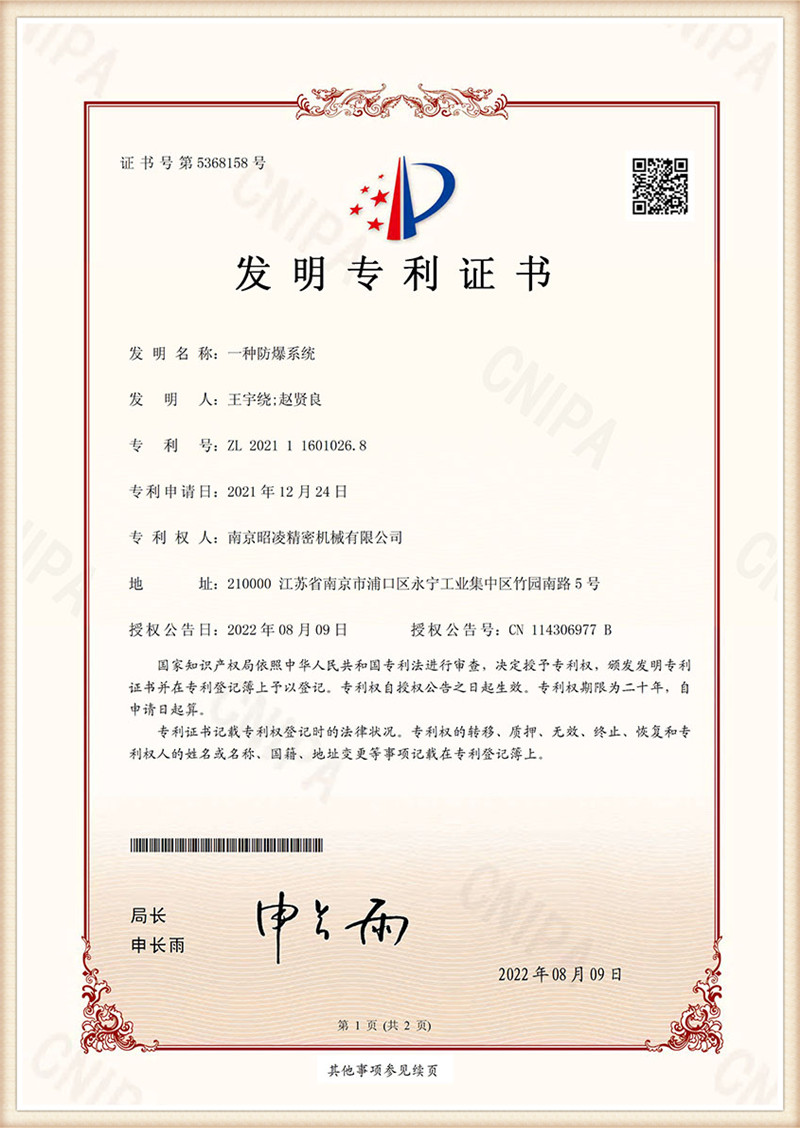

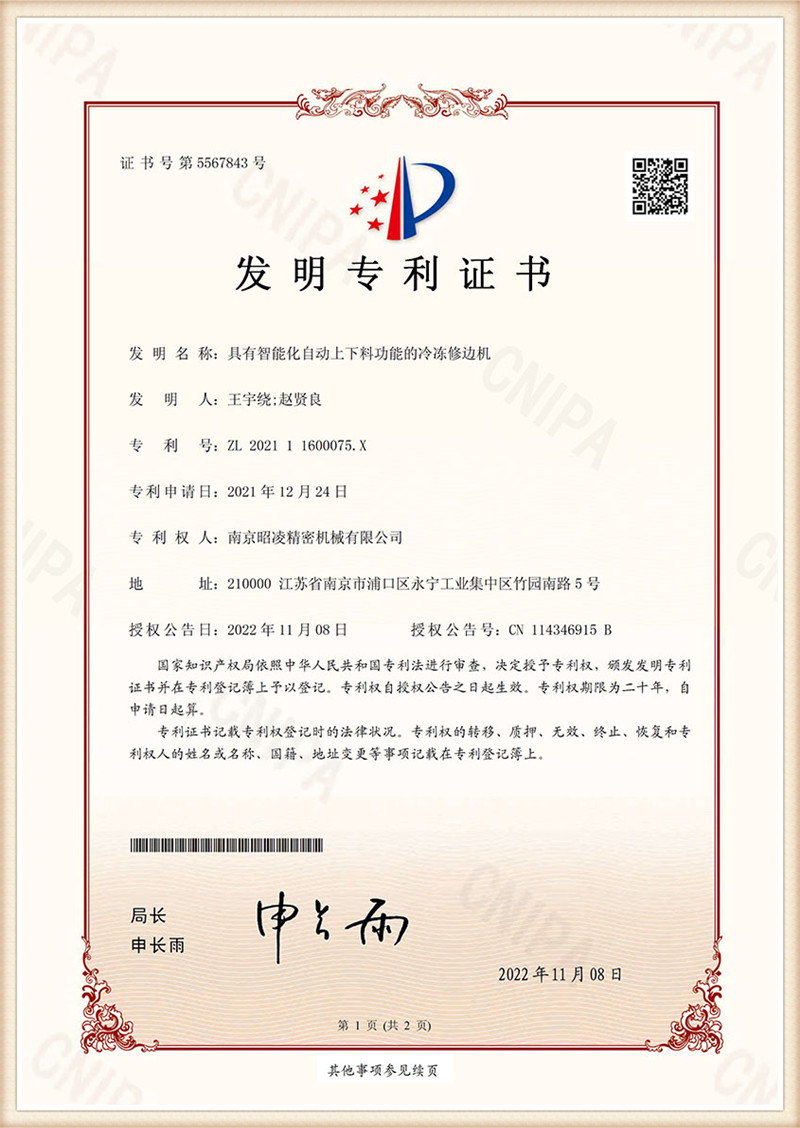

STMC obtained 6 software copyrights and 5 patent authorizations, including 2 invention authorizations, and acknowledged as national high-tech enterprise; national scientific and technology enterprise, national innovative enterprise, and Jiangsu scientific and technology private enterprise.